Shine Machinery Wood Chipper for Sale

A waste wood crusher is a special equipment specially used for crushing waste materials (such as edges, wooden pallets, branches, plates, etc.) produced during wood processing into small-sized particles by mechanical force.

Product Details

Core Function

Volume reduction treatment: compress a large volume of waste wood to 1/5~1/10 of the original volume, reduce transportation/storage cost

Resourceful pre-treatment: provide qualified raw materials for making biomass fuels, artificial boards, organic mulch, etc.

Environmental compliance: replacing incineration/landfill, meeting the requirements of the Solid Waste Pollution Prevention and Control Law.

Product Features

High-efficiency crushing: adopting high hardness alloy knives/hammer blades, with long service life and a 30% increase in crushing efficiency.

Intelligent control: optional PLC system, real-time monitoring of the operating status, to avoid overload.

Environmental protection and low noise: closed design to reduce dust spillage, in line with environmental standards.

Safe and reliable: Equipped with emergency brake and anti-bounce device, CE/ISO certified.

Multi-scenario application: support customized feed opening size, adaptable to different wood types.

Product Parameter

Application Scenarios and Value

1. Typical application

Furniture manufacturing: processing edgebanding, sawdust, unqualified boards

Artificial board production: the crushed material is used as raw material for OSB board and density board.

Energy utilization: crushed wood chips are used for biomass boiler/power generation.

Gardening: tree branches are crushed to make organic mulch or compost.

2. Economic and Environmental Benefits

Cost saving: transportation cost is reduced by 60%-80%.

Value-added benefits: the selling price of the crushed material can be 3-5 times of the original waste material

Carbon emission reduction: 1 ton of waste wood recycling ≈ reduces 0.8 tons of CO₂ emissions

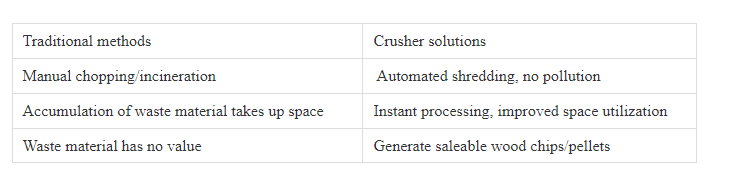

Advantages of Conventional Processing

Maintenance Points

Daily inspection: tool wear, bearing lubrication (lithium grease recommended)

Monthly maintenance: screen replacement, bolt tightening (torque ≥ 220N-m)

Annual overhaul: spindle dynamic balance test, hydraulic system pressure calibration

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close