Shine Veneer Dryer:Redefining Veneer Drying Standards

Shine Veneer Dryer: Where Engineering Excellence Meets Enduring Performance

In the fiercely competitive realms of woodworking and panel production, securing uniform veneer quality alongside peak production efficiency is a non-negotiable priority. SHINE Veneer Dryers rise above the fray thanks to rigorous engineering, rugged build quality, and the synergy of globally respected components. Every facet—from smart material-handling setups to next-generation thermal regulation—is purpose-built to guarantee steady operation, energy savings, and minimal unplanned stoppages.

Smart Solutions for Material Flow

SHINE’s ingenuity centers on intelligent material movement. The Automatic Loading arrangement integrates a Vacuum Suction System, Veneer Separator, Lifting Tables, and Chain Conveyors, orchestrating exact sheet separation and fluid transfer into the drying chamber. This cuts reliance on manual handling and trims labor expenses. For adaptable workflows, the Semiloading layout brings together a Conveying Belt, Chain Conveyor, Lifting Tables, and a Veneer Sorting Device, streamlining the gathering and arrangement of finished veneer. Meanwhile, the Semi Automatic Loading package—with a Veneer Separator, Lifting Tables, and Chain Conveyor—provides a budget-friendly option that preserves output levels. Together, these configurations curb handling mistakes and amplify production volume.

Sturdy Framework for Unwavering Stability

The dryer’s skeleton is forged from 100% high-grade section steel that complies with exacting national benchmarks. Its considerable mass and structural integrity deliver remarkable steadiness at high operating speedsing vibrations that might undermine drying consistency or shorten mechanical life. Such a resilient form ensures dependable service year after year, even amid round-the-clock industrial demands.

Optimized Heat Regulation for Energy Efficiency

Maintaining even temperature spread and energy effectiveness is pivotal in veneer drying. SHINE units deploy finned tube radiators that achieve a notable thermal efficiency above 92%. Teamed with a sophisticated hot air circulation system, these radiators disperse warmth uniformly around the chamber. Stable thermal conditions are essential for managing veneer moisture content, sidestepping over-drying or patchy curing that can mar end-product quality.

Exceptional Insulation and Hard-Wearing Parts

To hold internal heat and slash energy waste, SH aluminum silicate rock wool insulation at least 7.5 cm thick. This substance boasts superb heat retention, lowering running costs and environmental footprint. Components subject to motion, such as bearings, are fashioned from stainless steel resistant to high temperatures, selected for its lasting performance and resilience to corrosion under severe thermal shifts.

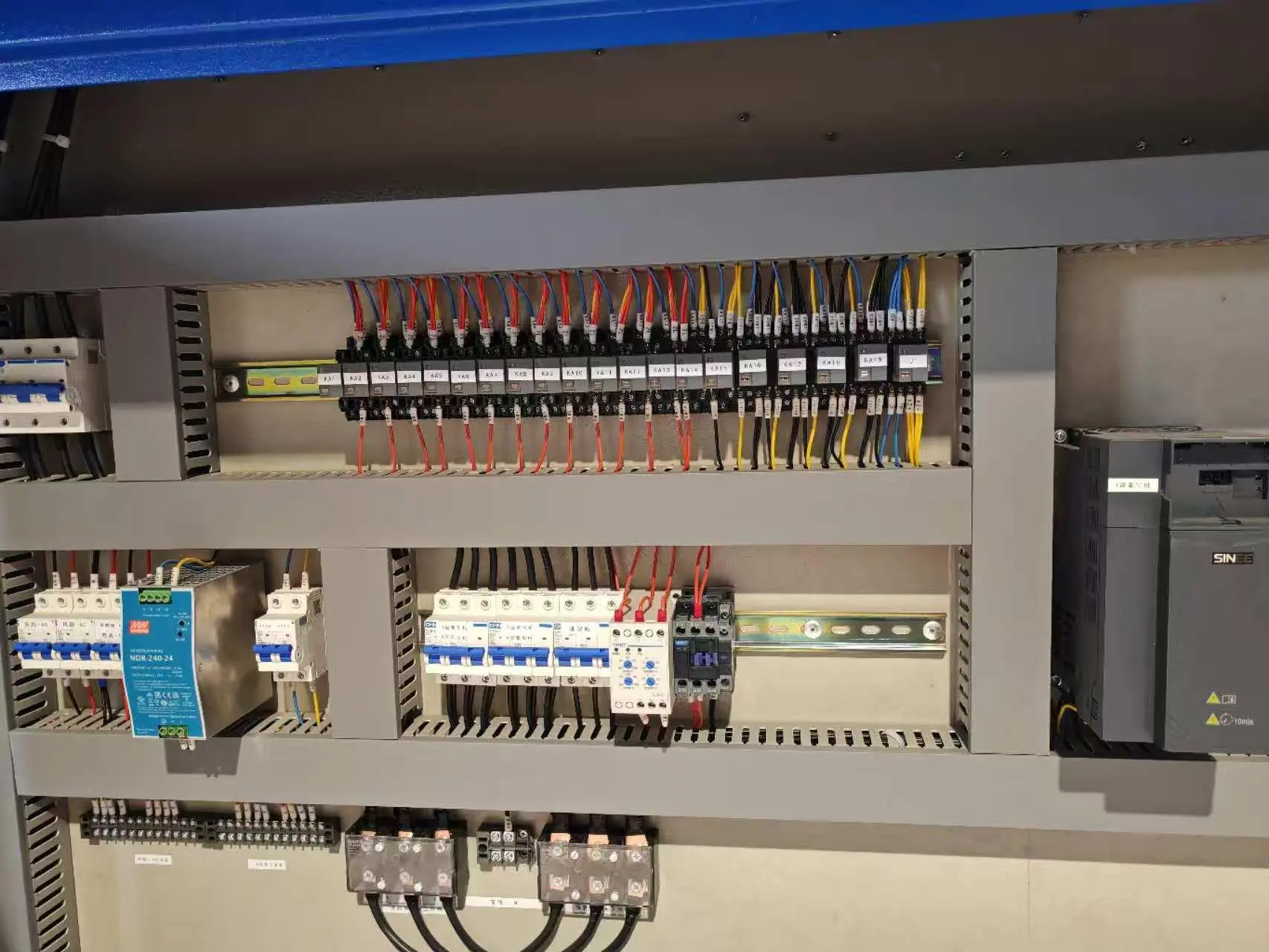

Trusted Electronics and Control Architecture

Accuracy in control comes from partnering with industry leaders. The Schneider relay, in tandem with PLC networks, yields an exceptionally low malfunction rate, keeping automated sequences running smoothly. For precise production tracking, an Omron encoder tallies veneer sheets during automatic loading and unloading, facilitating live oversight and workflow refinement The electrical cabinet, produced in-house by SHINE, prioritizes safe operation and straightforward upkeep. It offers user-friendly controls, full wire identification, and built-in safeguards like overload protection and leakage protection, shielding both personnel and machinery.

Purposeful Airflow Engineering

The distinctive axial flow fan with 8 blades is crafted for lasting performance and reliability. Its well-balanced build curbs wear, extending service life and lessening failure risks. Supporting this, air ducts formed from galvanized sheet metal feature a sawtooth thread pattern. This inventive design prevents veneer jams—a frequent headache in traditional setups—while a 200 mm width and 1 mm thickness preserve strength under high airflow forces.

Epilogue: Redefining Veneer Drying Standards

By merging advanced automation, finely tuned thermal technology, and best-in-class parts, SHINE Veneer Dryers establish a fresh standard for performance and trustworthiness. Whether powering large industrial plants or niche workshops, they assure repeatable results, efficient processes, and confidence through reduced upkeep and extended operational availability. Choosing a SHINE dryer is a commitment to enduring quality, heightened efficiency, and a forward-compatible answer for shifting manufacturing needs.