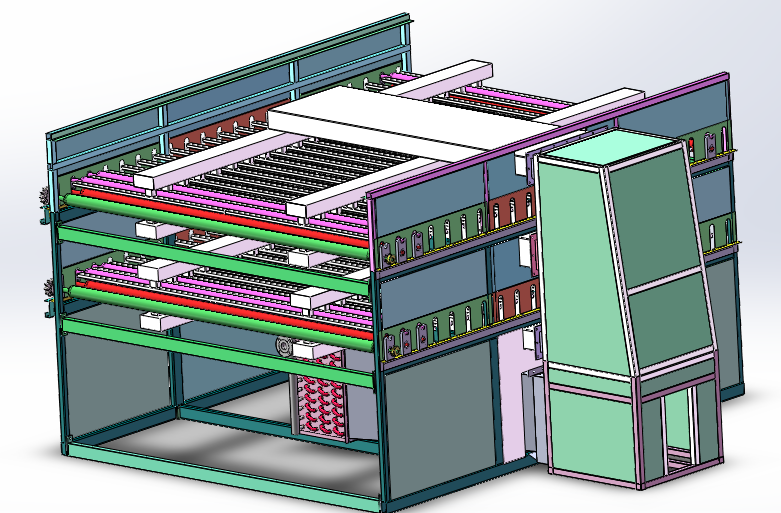

Small Dryer Customized for Plywood

The veneer dryer is an essential part of equipment in the plywood production process, and the drying quality of the veneer largely determines the final quality of the plywood. Some small-scaled plywood factories have relatively small veneer drying needs but aim for high-quality drying results. In such cases, Shine roller dryers are the top choice. They can be customized based on the customer's production capacity and also the factory size. Small dryer also can be used for those customers who wish to do veneers experiments in their workshop, the size can be short as much as possible.

Product Details

Usage Scenarios for Small Dryers:

Low production capacity, high requirements;

Secondary veneer drying (re-drying of veneers);

Limited workshop space.

The drying output for small dryer can be from 5m3 to 50m3 per day, with the dryer length up to 16meters. Here is one of the small dryer solution for the technial details:

Model No | GTH30-4 |

Working Width | 3m |

Deck | 1 |

Roller material | Q235B, φ 89 special shaft tube |

Heating area length | 3.96m |

Cooling area length | 0(Natural cooling) |

Veneer thickness | 1.5mm; 2.1mm |

Veneer water moisture | From 12% to about 3- 5% |

Heating material | Gas |

Veneer transport speed | 5-22m/min, 16A chain |

Power of Hot Air Blower | 5.5KW (1 pc) |

Power of Traction Motor | 2.2KW, frequency control (1 pc) |

Total Power | 7.7KW |

Actual electricity consumption | About 5kwh per hour |

Dimension(L*W*H) | 4m×3.5m×1.5m (main body) |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close