Shine Customized Conveyor Mesh Belt Suppliers

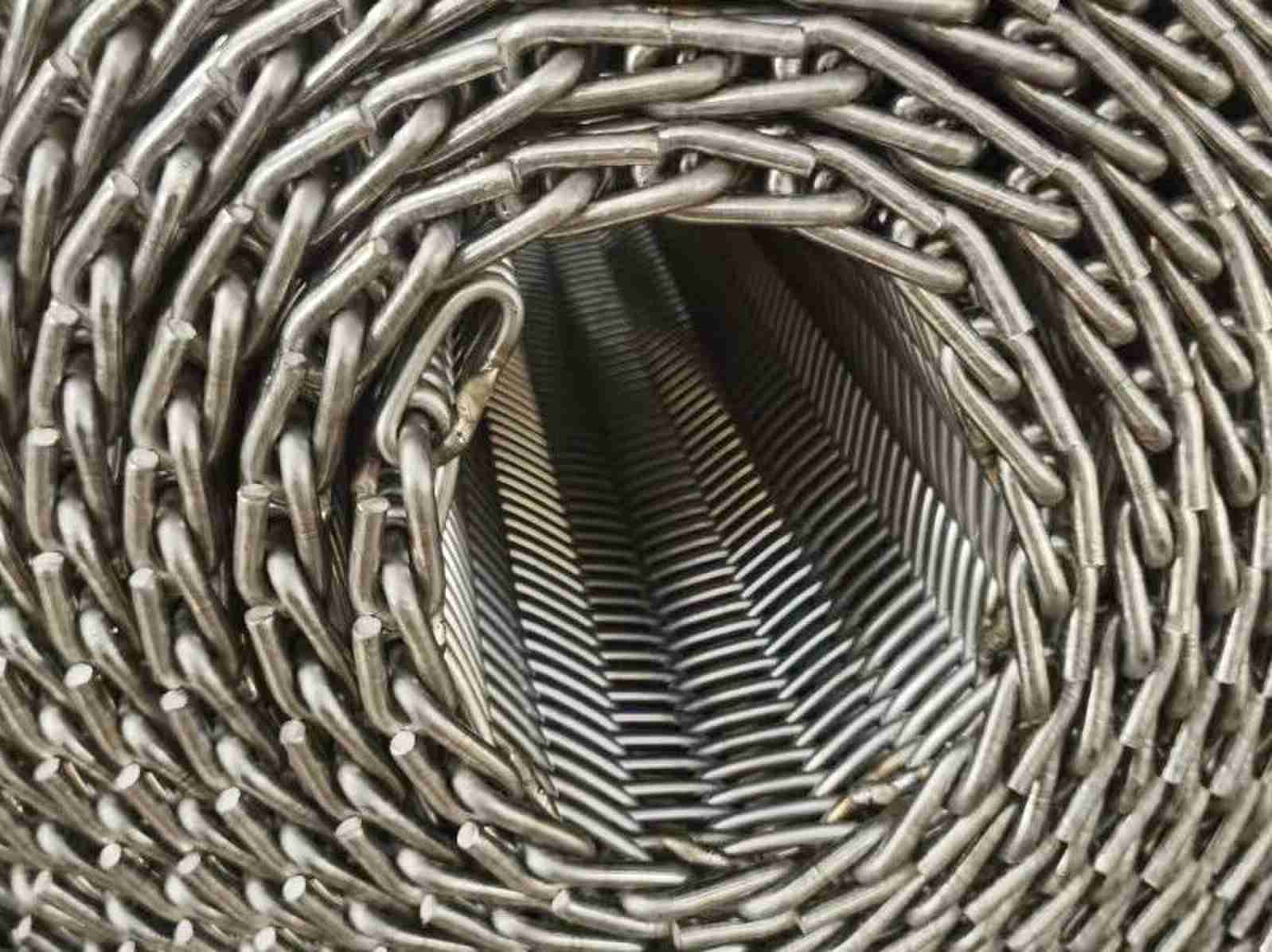

Mesh belt for dryer is the core component of drying equipment, which is made of high-quality stainless steel (such as 304, 316, or high-temperature resistant alloy) woven or welded, featuring high temperature resistance, corrosion resistance, anti-stretching, and so on. Widely used in food, chemical, metallurgy, building materials, environmental protection, and other industries, suitable for particles, flakes, and block material continuous drying operations.

Product Details

Key Features

1. Designed for the Woodworking Industry

Suitable for all kinds of wood drying scenarios: solid wood lumber, veneer (rotary cutting/planing), wood chips, wood chips, wood-plastic composites, and so on.

Special non-slip structure design (optional crossbar or wavy surface) prevents thin wood chips from curling or shifting.

2. Strong Resistance to Moisture and Heat Corrosion

316L stainless steel or titanium alloy is used to resist corrosion of wood, volatile acidic substances (such as acetic acid and formaldehyde).

The surface can be passivated to prolong the life of the mesh belt (more than 50% higher than an ordinary mesh belt).

3. High Temperature Adaptability

Temperature range 80℃~300℃, matching the temperature demand of the wood drying section (preheating-drying-cooling).

Low coefficient of thermal expansion, avoiding high temperature deformation caused by the running problem.

4. Efficient Air Permeability

Mesh opening rate 40%~60% (customizable), balanced hot air penetration, and material carrying capacity.

Support a two-way airflow design (upper and lower air supply at the same time) to improve the drying uniformity.

Exclusive Structure for the Woodworking Industry

Veneer Drying Mesh Belt: Ultra-thin (0.5~1.2mm thickness) + Precision weaving to avoid scratching precious wood veneer (e.g., walnut, mahogany).

Flake/fiber mesh belt: Reinforced edge design to prevent debris leakage.

Heavy-duty plate mesh belt: Thickened chain plate type structure, load capacity up to 200kg/m².

Why Choose Our Mesh Belt?

✅ Anti-clogging design: special hole arrangement reduces resin and wood tar adhesion (self-cleaning model is optional).

✅ Low maintenance cost: modular splicing, localized damage can be quickly replaced, reducing downtime loss.

✅ Intelligent adaptation: supports linkage with PLC system, real-time monitoring of tension, and runout warning.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close