How Important of a Veneer Grading System?

Veneer Grading: How Shine ’s Intelligent System Unlocks Hidden Value

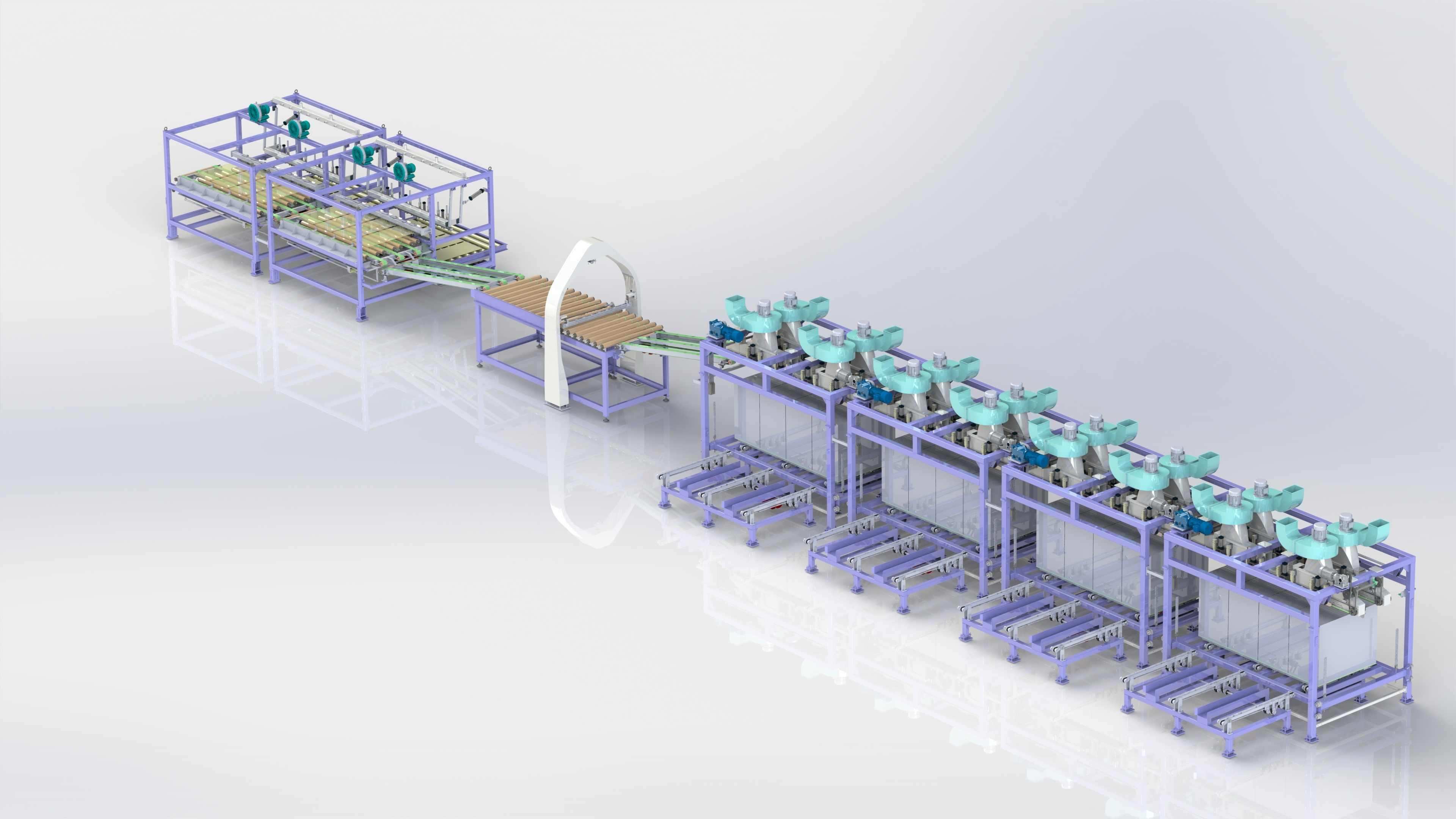

In the highly competitive world of wood processing, the margin between profitability and loss often hinges on the ability to maximize the value of every single raw material. For veneer-based products, this critical function is fulfilled by one indispensable process: veneer grading. Far from being a simple sorting task, veneer grading is a sophisticated quality management and value-optimization strategy that directly impacts a manufacturer's market positioning, operational efficiency, and bottom line. Recognizing this, Shine Machinery has pioneered the development of an integrated, intelligent veneer grading system, combining precise moisture detection and advanced vision technology to bring unprecedented accuracy and automation to this crucial stage of production.

Veneer, a thin sheet of wood peeled from a log, is a natural material with inherent variations. These variations—including knots, color differences, grain patterns, and structural defects—determine its ultimate suitability and value for different applications. The traditional manual grading process, reliant on the experienced but fallible human eye, is slow, inconsistent, and subject to fatigue. This leads to misclassification, where high-value veneer might be undervalued or flawed veneer might be passed to a premium client, damaging brand reputation. Shine Machinery 's intervention addresses these challenges at their core, transforming grading from an art into a precise science.

The Shine Machinery Intelligent Grading System: A Two-Pillar Approach

The company’s system is built on two integrated technological pillars that work in concert to deliver a comprehensive quality assessment.

1. Precision Moisture Content (MC) Detection:

Before any visual assessment can be meaningful, the veneer must be uniformly and appropriately dried. Uneven moisture is a primary cause of warping, delamination, and poor glue adhesion in the final product. Shine Machinery’s system incorporates non-contact, in-line moisture sensors that scan every inch of the veneer sheet immediately after drying. This provides an instant and accurate moisture profile, ensuring that only veneer within the optimal moisture range (typically 6%-12%) proceeds to visual grading. Veneer with high or uneven MC can be automatically flagged for re-drying or diverted for lower-value applications, preventing costly quality failures downstream. This step is the foundational guarantee of product stability.

2. Advanced Multi-Spectral Vision Inspection System:

This is the intelligent "eye" of the operation. High-resolution cameras capture detailed images of both veneer surfaces. The system's sophistication lies in its software, which uses complex algorithms to analyze key grading criteria:

Natural Defects: Automatically identifying and quantifying knots (size, type), cracks (length, width), insect holes, and mineral streaks.

Grain & Color Analysis: Classifying veneer based on grain pattern (straight, figured, burl) and color uniformity, which are critical for aesthetic applications like furniture faces and architectural paneling.

Processing Defects: Detecting issues from earlier stages, such as thickness variations, surface tear-out, or rough edges.

The system compares the analyzed data against predefined grading rules—which can be customized to international standards (e.g., HPVA) or a manufacturer’s specific requirements—to assign a grade (e.g., A, B, C, D) with unwavering objectivity.

The Tangible Benefits: Why Intelligent Grading is a Strategic Investment

The implementation of Shine Machinery 's automated system delivers a rapid return on investment across multiple facets of the business.

Maximized Revenue through Value-Based Sorting: By accurately identifying A-grade veneer with flawless aesthetics, manufacturers can command premium prices from clients in the high-end furniture and interior design sectors. Conversely, structurally sound but visually flawed veneer is correctly assigned to core or backer applications, ensuring no material is wasted and every sheet is sold at its optimal price point.

Enhanced Operational Efficiency and Throughput: The automated system operates at production line speeds, processing veneer continuously without pause. This eliminates the bottleneck created by manual inspection, significantly increasing the overall throughput of the production line and reducing labor costs associated with skilled graders.

Unprecedented Consistency and Quality Assurance: Human graders, no matter how skilled, have inherent inconsistencies due to fatigue, subjective interpretation, and changing light conditions. Shine Machinery’s system provides 100% consistent application of the grading rules 24/7, building unwavering trust with customers who rely on receiving a uniform product batch after batch.

Data-Driven Process Improvement: The system doesn’t just sort; it collects vast amounts of data. Production managers can generate reports on defect rates, grade yields, and moisture statistics. This data becomes a powerful tool for root cause analysis, allowing managers to identify and rectify issues in the peeling or drying stages, thereby continuously improving upstream processes and increasing the overall yield of high-grade veneer.

Conclusion: Grading as a Cornerstone of Modern Manufacturing

In today's market, simply producing veneer is not enough. The ability to consistently sort and validate its quality is what separates market leaders from the rest. Shine Machinery’s intelligent veneer grading system represents a paradigm shift, elevating a necessary post-production step into a strategic center for value creation, quality control, and business intelligence. By automating and perfecting the art of veneer grading, Shine Machinery empowers manufacturers to unlock the full hidden value in every log, build a reputation for reliability, and secure a decisive competitive advantage in the global marketplace.