Why Stainless Steel Mesh Belts Are Essential for Drying Precious Veneers?

In the high-stakes world of fine woodworking and luxury interior design, the value of a finished product is profoundly influenced by the quality of its surface. Precious veneers, such as those sliced from Walnut and White Oak with a delicate thickness of 0.5mm or less, represent the pinnacle of natural aesthetics. These ultra-thin sheets are the canvases upon which masterpieces of furniture and architectural millwork are created. The process of drying these veneers is not merely a step in production; it is a critical juncture where millions of dollars in potential value can be either preserved or lost. In this sensitive and precise operation, the choice of drying technology—specifically the conveyor belt within the dryer—becomes a decisive factor. For industry leaders committed to uncompromising quality, the consensus is clear: stainless steel mesh conveyor belts are not an option but a necessity for drying the world's most precious veneers.

The journey of a veneer from a wet, fragile sheet to a stable, ready-to-apply facing is fraught with risk. Traditional drying methods using belts made from materials like galvanized steel or Teflon-coated polyester, while cost-effective for some applications, present unacceptable hazards for high-value woods. The primary mission in drying Walnut and White Oak is to preserve their unique, often irreplaceable, character—the deep, swirling grain of Walnut and the prominent ray flakes of White Oak. Any compromise during drying can permanently diminish this character, leading to substantial financial loss. It is at this crucial stage that the inherent properties of stainless steel belts deliver unparalleled advantages, directly addressing the core challenges of premium veneer production.

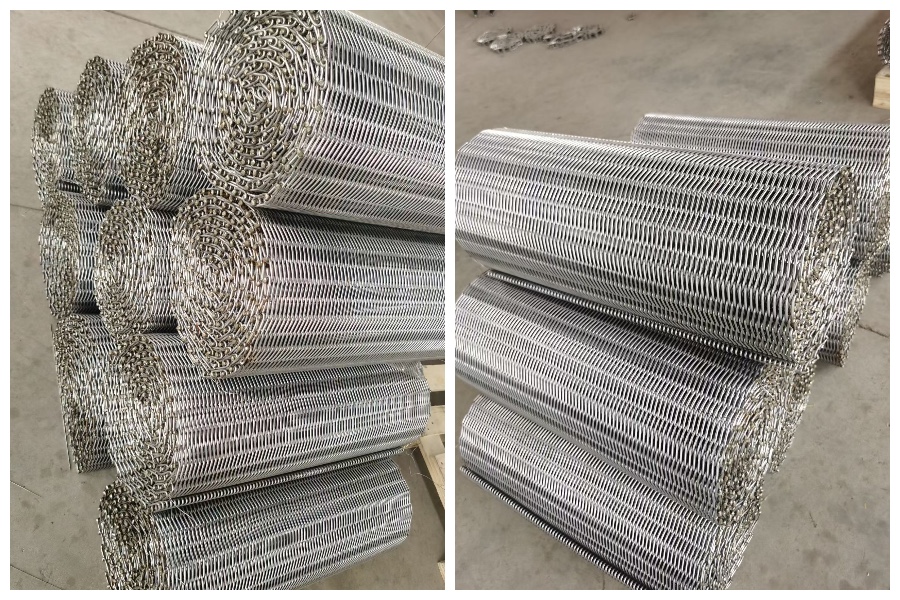

The first and most critical advantage is the absolute preservation of surface integrity. Precious veneers are exceptionally vulnerable to physical impression and chemical contamination. The hard, mirror-smooth, and non-porous surface of high-grade stainless steel provides a perfectly inert bed. Unlike galvanized belts, which can rust over time and transfer iron oxide stains to the light-colored sapwood of White Oak, stainless steel is highly corrosion-resistant. Furthermore, unlike Teflon coatings that can degrade and transfer onto the hot, moist wood, stainless steel offers a chemically pure surface. This guarantees that the veneer's underside remains unmarked, preserving the purity of the grain pattern that defines its value.

The second pillar of superiority is exceptional thermal and dimensional stability. Uniform drying is paramount to preventing warping, cracking, or the development of internal stresses that only manifest after the veneer is applied to a panel. Stainless steel exhibits minimal thermal expansion under the consistent heat of a dryer (typically operating between 120°C and 180°C). This stability ensures the belt remains perfectly taut and flat as it travels through the drying chamber. Belts made from other materials can stretch or deform with heat, creating uneven tension that leads to wrinkles, folds, or misalignment. These incidents not only jam the production line but also destroy the valuable veneer. The consistent flatness of a stainless steel belt ensures every square inch of the veneer receives identical heat exposure, resulting in a final product with perfectly even moisture content.

Third, the robust durability and hygienic properties of stainless steel translate directly to long-term operational reliability and cost savings. The environment inside a veneer dryer is punishing—a constant combination of heat, moisture, and acidic tannins released from the wood itself. Galvanized coatings wear thin, and carbon steel belts eventually succumb to rust. A high-quality stainless steel belt, manufactured from grades like 304 or 316, is inherently resistant to these corrosive forces. This resistance translates to a significantly longer operational lifespan, dramatically reducing the frequency of costly belt replacements and the associated production downtime. Moreover, the non-porous surface is easy to clean and prevents the buildup of sap and debris, which can otherwise bake onto the belt and create marks on subsequent veneer sheets.

For manufacturers seeking a complete solution, companies like Shine Machinery integrate these material advantages into engineered systems. They design dryers with precision-tensioned stainless steel belts, optimized mesh patterns for ideal laminar airflow, and tracking systems that ensure flawless operation. This holistic approach guarantees that the inherent benefits of the material are fully realized in practice.

In conclusion, selecting a drying system for precious veneers is a strategic investment. The choice of a stainless steel belt is a definitive commitment to quality, safeguarding the aesthetic and financial value of materials like Walnut and White Oak. It is the technological foundation for achieving the uniformity, purity, and reliability demanded by the most discerning clients in the high-end woodworking industry. In an arena where perfection is the only acceptable standard, anything less than stainless steel represents an untenable risk.