Peeling Back the Layers: A Guide to Veneer Lathes

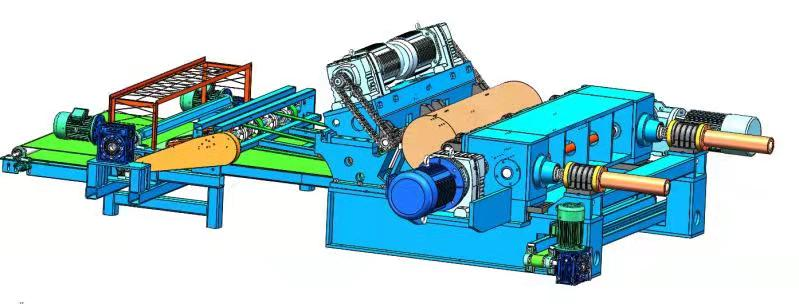

In the world of wood-based panel production, from plywood to LVL, the veneer peeling lathe stands as a cornerstone of the manufacturing process. The quality, efficiency, and economics of the entire operation hinge on this critical machine. For manufacturers, the choice between the two primary types of veneer lathes – spindleless and spindle – is a fundamental strategic decision. Understanding their distinct characteristics, supported by operational data, is key to optimizing production lines for specific raw materials and end-products.

While your equipment specifications, such as a line speed of 30m/min and a 2.2kW motor power, point to a capable system, the core differentiator lies deeper. This article delves into the technical realities of both spindle and spindleless lathes, using empirical data to illustrate their strengths and ideal applications.

The Spindle Lathe: Precision for Premium Products

The spindle lathe, the traditional workhorse of the industry, operates on a principle of immense mechanical force. It employs large-diameter spindles (or chucks) that pierce and clamp the log from both ends, rotating it against a stationary knife. This method provides unparalleled stability for the log during the peeling process.

Data-Driven Advantages:

Large Diameter Capacity: Spindle lathes are engineered to handle large-diameter logs, typically ranging from 400mm to over 1500mm. This makes them indispensable for processing valuable, old-growth timber.

Superior Veneer Quality: The rigid clamping at both ends, often supplemented by pressure bars along the length, minimizes log deflection. This results in exceptionally consistent veneer thickness, with thickness variation often held within a tight tolerance of ±0.05mm. This precision is critical for producing high-quality face veneers for architectural plywood and furniture, where surface perfection is paramount.

High Driving Power: The direct drive system allows these machines to transmit significant power, often ranging from 150kW to over 400kW for the main drive, enabling them to peel the densest hardwood species without slippage.

However, this robust design comes with a significant drawback: the core loss. The spindles leave an unpeelable core, typically 150mm to 250mm in diameter. For a log with an initial diameter of 800mm, this represents a wood yield loss of approximately 6-10%. In high-volume production, this waste accumulates into a substantial cost.

The Spindleless Lathe: Efficiency for Maximized Yield

Developed to address the core waste issue and adapt to changing timber resources, the spindleless lathe operates on a radically different principle. It eliminates the end-clamping spindles altogether. Instead, the log is driven entirely by friction from powered rollers pressing against its periphery, while being held firmly against the knife bed.

Data-Driven Advantages:

Near-Zero Core Waste: This is the most significant advantage. A spindleless lathe can peel a log down to a core of just 50mm to 90mm. This increases overall wood yield by 5-15% compared to a spindle lathe. In an era of rising timber costs, this efficiency directly boosts profitability.

Small Log Proficiency: These machines excel with small-diameter logs, efficiently processing diameters from 50mm up to 650mm. This aligns perfectly with the industry's shift towards plantation-grown and fast-rotation species.

Continuous Operation: Many modern spindleless lathes feature automatic log loaders, allowing for a near-continuous peeling process. As one log is being finished, the next is positioned, drastically reducing non-productive time and increasing overall machine throughput.

The trade-off lies in the veneer characteristics. The friction-driven system can be susceptible to slippage with irregular or slippery logs, potentially leading to slight variations in thickness (e.g., ±0.1mm or more). The veneer is also typically wound into a continuous ribbon, which is excellent for later clipping but may exhibit more "loose backs" or micro-cracks compared to the sheets produced by a spindle lathe. Therefore, it is ideally suited for core veneers in plywood, or for the production of LVL, where ultimate surface aesthetics are less critical than structural integrity and cost-effectiveness.

Making the Strategic Choice: Data in Action

The choice is not about which machine is "better," but which is optimal for a specific factory's context.

Choose a Spindle Lathe if: Your primary raw material is large-diameter logs (above 650mm) and your business focuses on high-value products like face veneers for export-grade plywood or decorative panels. The priority is precision quality, and the core waste is an acceptable cost for achieving it.

Choose a Spindleless Lathe if: Your operation relies on smaller-diameter plantation wood (50mm-650mm) and your primary products are core veneers, structural panels, or LVL. The driving factor is maximizing yield from every log to minimize raw material costs, and the veneer characteristics are fit for purpose.

The Future: Hybridization and Smart Technology

The evolution continues. We now see the emergence of "combination lathes," which can operate in both modes, offering manufacturers unprecedented flexibility. Furthermore, smart technologies are being integrated into both types. Automated centering systems, laser scanning for optimal rounding, and real-time thickness monitoring are becoming standard, pushing the boundaries of efficiency and quality regardless of the peeling principle.

In conclusion, the dichotomy between spindle and spindleless veneer lathes represents the industry's adaptive response to diverse economic and material constraints. By understanding the data behind their performance—from core diameter losses to thickness tolerances—manufacturers can make informed investments that ensure their operations remain competitive, efficient, and sustainable for years to come.