Industrial-Grade Efficiency for Plywood, Furniture & Decorative Veneer Production

The Shine double-layer veneer dryer is primarily used in the wood processing industry, particularly as a high-capacity plywood veneer machine for veneer drying. Shine veneer rolling dryer adopts a roller design, which is driven by a chain to rotate the upper and lower drums relative to each other. It uses hot air and other drying media to dry the veneer, compared to common dryers on the market, which have the advantages of simple operation, smooth operation, low veneer jamming, easy maintenance, and low moisture content.

Product Details

Key Features & Advantages

✅ Dual-Chamber Design for Maximum Output

Simultaneous 2-layer drying – Processes 50% more veneer vs single-layer dryers

Independent temperature control per layer for mixed-thickness batches (0.5–8mm)

✅ Precision Moisture Control

Smart humidity sensors maintain 6–8% final moisture content (meets customers' request)

Auto-balancing airflow prevents warping/cracking (±0.5% moisture variance across layers)

✅ Energy-Saving Innovation

Heat recovery system recycles 30% waste heat (cuts gas/electric costs by $8,000+/year vs conventional dryers)

Low-Temp Drying Mode for heat-sensitive species

✅ Industrial Durability

304 stainless steel mesh belts withstand 10+ years of continuous use

Corrosion-resistant frame (EPOXY coating for humid environments)

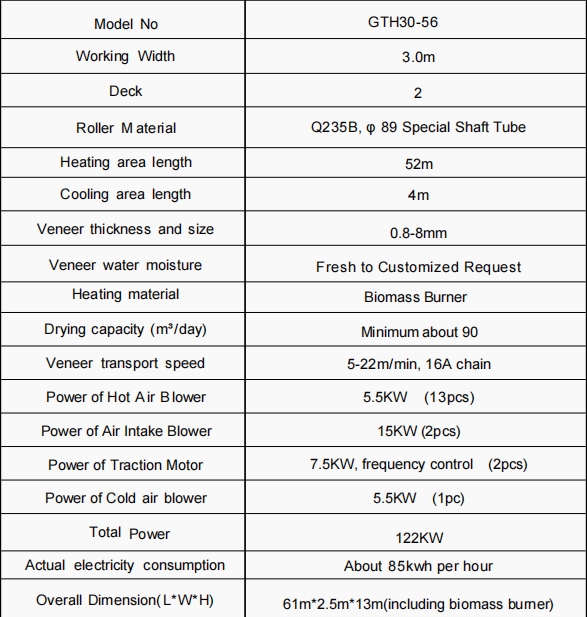

Technical Specifications

Application Scenario

Plywood Factory: As one of the important pieces of equipment for plywood production, the core veneer dryer machine can dry the veneer efficiently and evenly to provide high-quality raw material for subsequent plywood production.

Building Formwork: During the production of building formwork, wood needs to be dried to improve its stability and durability. Shine rolling veneer dryers can meet this need and provide strong support for the production of building templates.

Furniture Manufacturing: Furniture manufacturing often uses a variety of panels as raw materials. Shine dryers can ensure the drying quality of the boards and improve the overall quality of the furniture.

Other Wood Processing Industries: Wood processing industries such as flooring, wooden doors, wooden lines, etc., also need to dry the wood. With its advantages of labor cost, environmental protection, and energy saving, the Shine dryer also has a wide range of application prospects in these fields.

Company Strength

In the pursuit of high-efficiency environmental protection and quality in the wood processing industry, as a veneer dryer manufacturer, Shine has become a bright star in the industry with its excellent performance, advanced technology, and intelligent design. We know that drying is not only the key step to ensure the stability of the veneer in every process of veneer but also the foundation to improve the quality of the product and prolong its service life. Therefore, Shine has elaborated a series of high-efficiency veneer dryers aiming to bring an unprecedented drying experience for global wood processing enterprises.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close