New-Designed Vertical Veneer Dryer with Lower Cost

Compared with the roller dryer, the Shine vertical veneer dryer has a smaller output. This is mainly due to the relatively

simple structure of the vertical veneer dryer and the limited drying area, so the amount of wood processed in a single pass is small.

However, for many small and medium-sized wood processing enterprises, this output is sufficient to meet their daily production

needs. The Shine vertical veneer dryer has a lower cost. This is due to its simpler mechanical structure and lower manufacturing costs.

By optimizing the production process and adopting efficient production technology, the company has successfully reduced the

manufacturing cost of the equipment, thus providing customers with more cost-effective products.

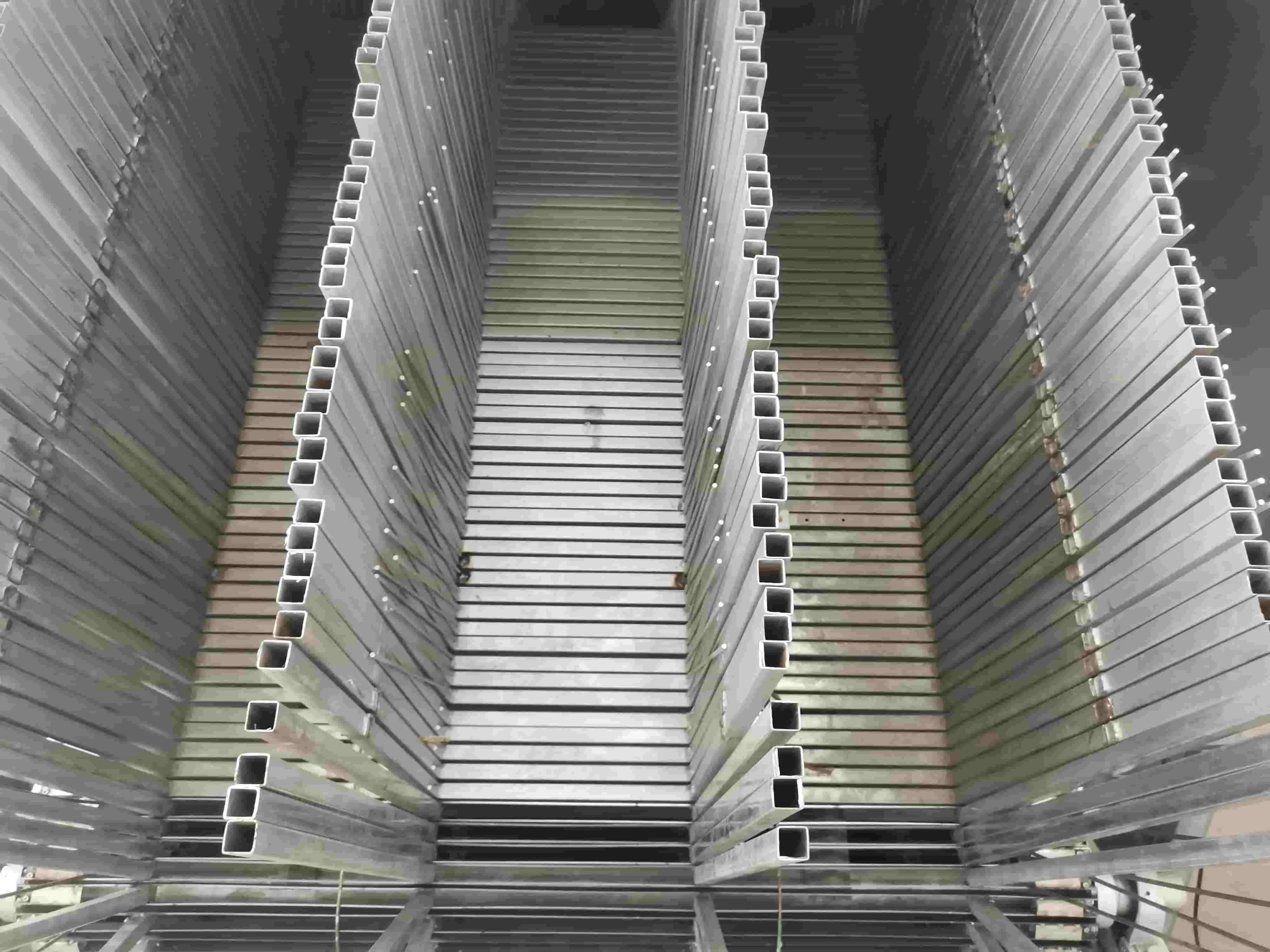

Product Details

Advantages of New-Designed Vertical Veneer Dryer with Lower Cost

Shine vertical veneer dryer is widely used in small and medium-sized wood processing enterprises, furniture manufacturing factories, decoration material production

factories, and other fields. These customers do not have high requirements on the equipment output but have high requirements on the price, performance, and

stability. Shine vertical veneer dryer has won a good reputation and wide recognition in the market with its excellent cost and stable performance.

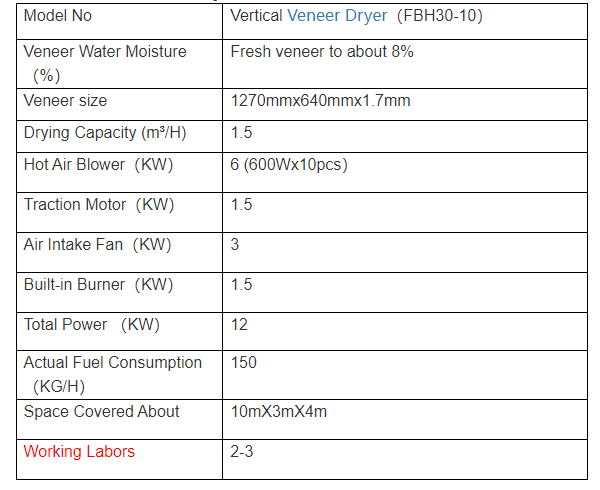

The main technical and parameter

Application Scenario

Plywood Factory: As one of the important pieces of equipment for plywood production, the veneer dryer can dry the veneer efficiently and evenly to provide high-quality raw material for subsequent plywood production.

Building Formwork: During the production of building formwork, wood needs to be dried to improve its stability and durability. Shine dryers can meet this need and provide strong support for the production of building templates.

Furniture Manufacturing: Furniture manufacturing often uses a variety of panels as raw materials. Shine dryers can ensure the drying quality of the boards and improve the overall quality of the furniture.

Other Wood Processing Industries: Wood processing industries such as flooring, wooden doors, wooden lines, etc. also need to dry the wood. With its advantages of labor cost, environmental protection, and energy saving, the Shine dryer also has a wide range of application prospects in these fields.

Certification

Customer Visit

Exhibition

Company Strength

In the pursuit of high-efficiency environmental protection, and quality in the wood processing industry, as a veneer dryer manufacturer, the Shine has become a bright star in the industry with its excellent performance, advanced technology, and intelligent design. We know that drying is not only the key step to ensure the stability of the veneer in every process of veneer but also the foundation to improve the quality of the product and prolong its service life. Therefore, Shine has created a series of high-efficiency veneer dryers aiming to bring an unprecedented drying experience to global wood processing enterprises.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close