Customized Roller Wood Veneer Making Machine Plywood Veneer Drying Equipment

Shine's wood veneer making machine are usually equipped with biomass burners that can directly burn biomass fuels such as bark, combining the advantages of environmental protection, high efficiency, and energy conservation. Compared to traditional steam or thermal oil furnace dryers, its drying cost is significantly reduced, achieving resource recycling and maximizing value, in line with the environmental protection concept of sustainable development.

Product Details

Customized Roller Wood Veneer Making Machine Plywood Veneer Drying Equipment

Shine's Wood Veneer Dryer is main machine for plywood making line, it's used for wood veneer drying and the roller type dryer has the best drying effect, the surface of the dried veneer is the most flat, no cracking, it is the first choice of high quality veneer manufacturers. Shine's equipment always be customized according to customer's requirements. It's high efficiency, saving energy and improving the veneer quality. It is conomical and reduces the moisture content of veneers by means of the least loss of the plates. The process of making it meet the process requirements. The veneer dryer is composed of a transmission chamber, a drying chamber, a cooling chamber and so on.

Advantages Of Customized Roller Wood Veneer Making Machine Plywood Veneer Drying Equipment

Accurate temperature and humidity control system: The temperature and humidity conditions required in the drying process can be accurately set by the automatic feeder system and maintained to ensure the stability and consistency of veneer drying quality.

Good drying uniformity: Whether it is the center or the edge of the veneer, it can ensure the uniformity of heat and moisture distribution, which makes the quality of the veneer after drying uniform.

Better environmental performance: For example, the exhaust gas generated by the combustion of the hot air furnace after scientific treatment, is in line with environmental emission requirements.

Convenient maintenance: A reasonable structural design makes daily maintenance convenient and quick, reducing equipment downtime and maintenance time.

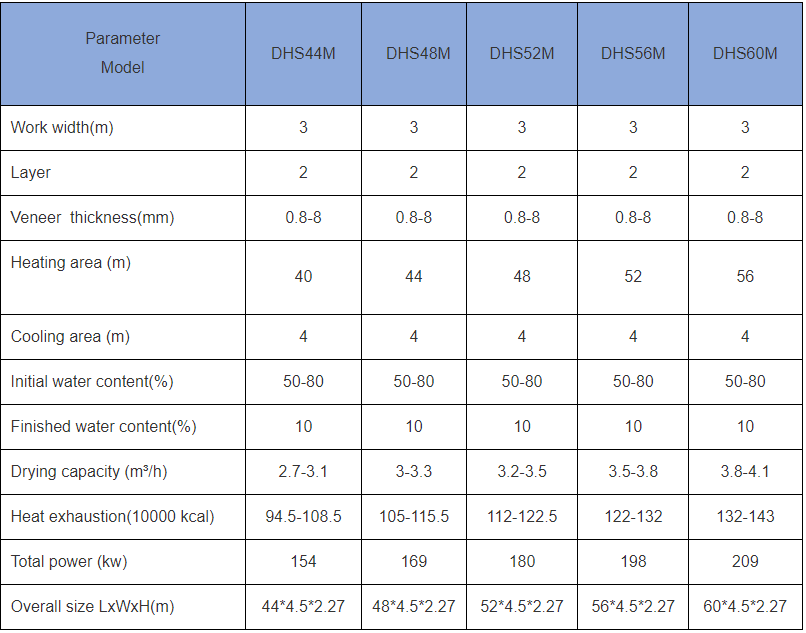

Adapt to different production scales: According to the customer's actual production demand, customize different sizes and capacities of the dryer.

Good flatness maintenance: The drying process can minimize the veneer warping, deformation, and other problems, to ensure that the veneer drying still maintains a good flatness.

As a machine manufacturer, we have a professional R&D team that can provide customized services and requests for different models.

The perfect after-sale service team can supply 24-hour online service.

Application Scenario

Plywood Factory: As one of the important pieces of equipment for plywood production, the veneer dryer can dry the veneer efficiently and evenly to provide high-quality raw material for subsequent plywood production.

Building Formwork: During the production of building formwork, wood needs to be dried to improve its stability and durability. Shine dryers can meet this need and provide strong support for the production of building templates.

Furniture Manufacturing: Furniture manufacturing often uses a variety of panels as raw materials. Shine dryers can ensure the drying quality of the boards and improve the overall quality of the furniture.

Other Wood Processing Industries: Wood processing industries such as flooring, wooden doors, wooden lines, etc. also need to dry the wood. With its advantages of labor cost, environmental protection, and energy saving, the Shine dryer also has a wide range of application prospects in these fields.

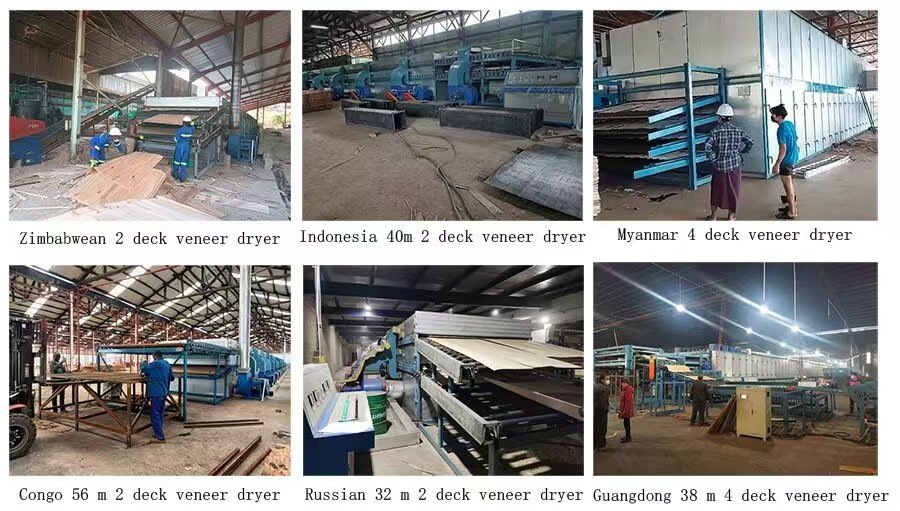

Customer Case

Packaging & Shipping

Company Strength

In the pursuit of high-efficiency environmental protection, and quality in the wood processing industry, as a veneer dryer manufacturer, the Shine has become a bright star in the industry with its excellent performance, advanced technology, and intelligent design. We know that drying is not only the key step to ensure the stability of the veneer in every process of veneer but also the foundation to improve the quality of the product and prolong its service life. Therefore, Shine has elaborated a series of high-efficiency veneer dryers aiming to bring an unprecedented drying experience for global wood processing enterprises.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close