Roller Type Wood Veneer Drying Machine For Plywood Production Line

Shine's roller wood veneer dryer as an important section of plywood production line, the main advantages include large output, energy saving, high drying efficiency and so on, The veneer dryer is mainly used for drying core veneer to solve the problem of high moisture content after stripping. It is suitable for drying veneer with thickness of around 0.8mm-8mm. The waste wood produced in the process of veneer rotary cutting is used as fuel, realizing the local material, turning waste into treasure, and greatly reducing the energy cost in the drying process.

Product Details

Roller Type Wood Veneer Drying Machine For Plywood Production Line

Shine veneer dryer as the key equipment in plywood production line. Shine veneer dryer is a representative of high quality products, providing dry and flat veneer for various decorative finishes. The machine and key components are made of high quality materials and advanced manufacturing technology. It can also saving energy, adopting advanced heating technology and energy-saving design, compared with the traditional dryer can significantly reduce the unit energy consumption.

Advantages Of 4 Layers Core Veneer Roller Dryer

Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect.

The biomass burner is Shine patented product. It can burn all kinds of waste wood directly to reduce the drying cost to the most.

The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

The veneer after drying is free of splits and the surface is in good condition for gluing.

Shrinkage and casehardening is kept to a minimum and collapse and honeycomb are avoided.

Parameter Of Wood Veneer Dryer

Applications

Plywood Factory: As one of the important pieces of equipment for plywood production, the Shine dryer can dry the veneer efficiently and evenly to provide high-quality raw material for subsequent plywood production.

Building Formwork: During the production of building formwork, wood needs to be dried to improve its stability and durability. Shine dryers can meet this need and provide strong support for the production of building templates.

Furniture Manufacturing: Furniture manufacturing often uses a variety of panels as raw materials. Shine dryers can ensure the drying quality of the boards and improve the overall quality of the furniture.

Other Wood Processing Industries: Wood processing industries such as flooring, wooden doors, wooden lines, etc. also need to dry the wood. With its advantages of labor cost, environmental protection, and energy saving, the Shine dryer also has a wide range of application prospects in these fields.

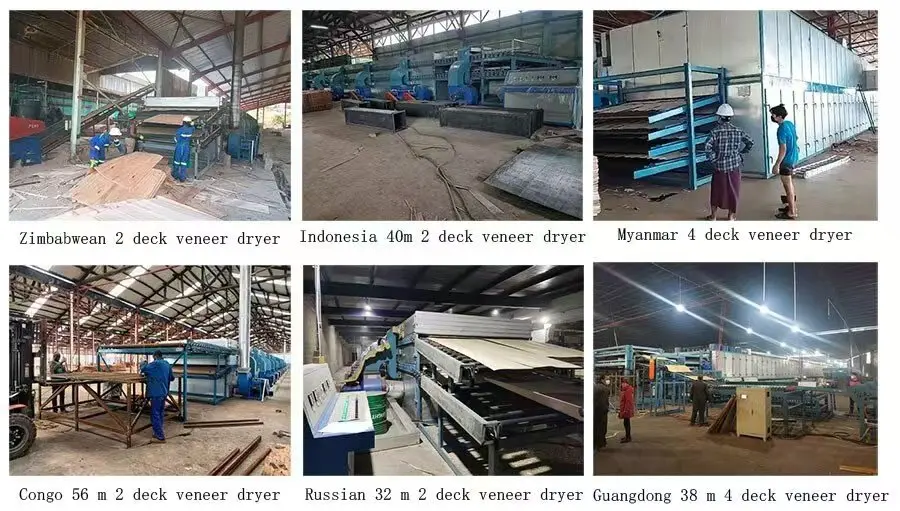

Customer Case:

Packing And Shipping

Company Strength

In the pursuit of high efficiency, environmental protection, and quality in the wood processing industry, as veneer dryer manufacture, the Shine has become a bright star in the industry with its excellent performance, advanced technology, and intelligent design. We know that drying is not only the key step to ensure the stability of the veneer in every process of veneer but also the foundation to improve the quality of the product and prolong its service life. Therefore, Shine has elaborated a series of high-efficiency veneer dryer, aiming to bring an unprecedented drying experience for global wood processing enterprises.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close