Shine Sawdust Wood Rusher Machine with High Efficiency

Maximize your wood processing productivity with our advanced machinery, designed for durability and performance. Our Wood Log Crusher Machine is engineered to break down large logs into smaller, manageable pieces, making it ideal for sawmills, biomass plants, and recycling facilities. A waste wood crusher is a special equipment specially used for crushing waste materials (such as edges, wooden pallets, branches, plates, etc.) produced during wood processing into small-sized particles by mechanical force.

Product Details

High-Efficiency Wood Processing Machinery for Industrial & Commercial Use

For heavy-duty applications, our Wood Crusher Industrial model delivers unmatched power, reducing wood waste, pallets, and branches into uniform chips or sawdust. Built with robust materials, it ensures long-lasting operation even in demanding environments. Additionally, our Commercial Wood Chipper is perfect for landscaping, forestry, and agricultural businesses, offering fast and efficient wood chipping with minimal maintenance. Whether you need fine mulch or coarse wood chips, this machine provides consistent results for professional use.

Product Features

High-efficiency crushing: adopting high-hardness alloy knives/hammer blades, with long service life and a 30% increase in crushing efficiency.

Intelligent control: optional PLC system, real-time monitoring of the operating status, to avoid overload.

Environmental protection and low noise: closed design to reduce dust spillage, in line with environmental standards.

Safe and reliable: Equipped with emergency brake and anti-bounce device, CE/ISO certified.

Multi-scenario application: supports customized feed opening size, adaptable to different wood types.

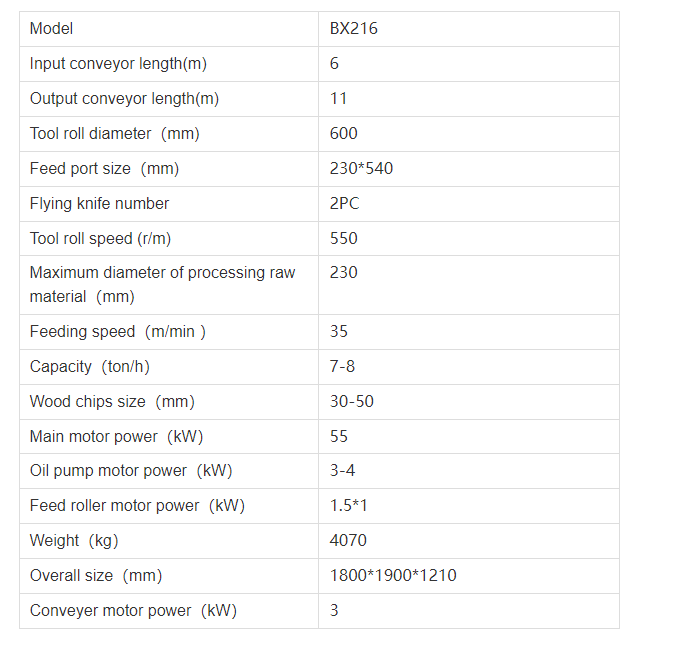

Product Parameter

Application Scenarios and Value

1. Typical application

Furniture manufacturing: processing edgebanding, sawdust, and unqualified boards

Artificial board production: The crushed material is used as raw material for OSB board and density board.

Energy utilization: crushed wood chips are used for biomass boiler/power generation.

Gardening: Tree branches are crushed to make organic mulch or compost.

2. Economic and Environmental Benefits

Cost saving: transportation cost is reduced by 60%-80%.

Value-added benefits: the selling price of the crushed material can be 3-5 times that of the original waste material

Carbon emission reduction: 1 ton of waste wood recycling ≈ reduces 0.8 tons of CO₂ emissions

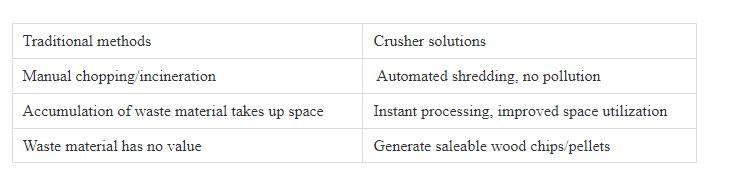

Advantages of Conventional Processing

Company Strength

In the pursuit of high-efficiency environmental protection and quality in the wood processing industry, as a veneer dryer manufacturer, Shine has become a bright star in the industry with its excellent performance, advanced technology, and intelligent design. We know that drying is not only the key step to ensure the stability of the veneer in every process of veneer but also the foundation to improve the quality of the product and prolong its service life. Therefore, Shine has elaborated a series of high-efficiency veneer dryers aiming to bring an unprecedented drying experience for global wood processing enterprises.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close