Industry News

In the realm of wood veneer manufacturing where excellence is pursued, the drying process is the ultimate proving ground that determines success or failure. When employing a roller veneer dryer, the guiding philosophy for treating veneer sheets from different tree species could not be more

2026/01/27 17:10

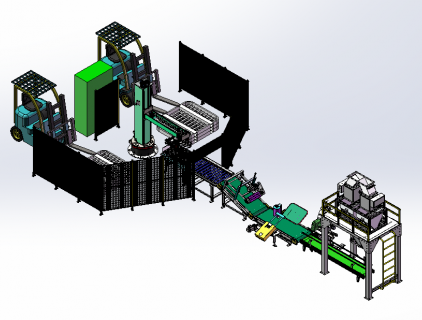

How Robotic Arm is Reshaping the Future of WoodworkingIn the global woodworking industry, the demand for precision, speed, and sustainability continues to rise. As manufacturers face mounting pressure to reduce costs, meet eco-friendly standards, and scale production, robotic arms have emerged as a

2026/01/08 16:07

Gentle Heat, Perfect VeneerIn veneer manufacturing, the drying phase is just as crucial as peeling and grading. When wood veneers pass through a mesh belt veneer dryer, you may notice the machine runs at a modest temperature and a slow belt speed. Far from being accidental, this method is a

2025/12/16 14:13

In the bustling production halls of today's plywood making industry, a silent revolution has solidified—quite literally. The shift towards synthetic resin adhesives for the glue-spreading step is more than a trend; it's a fundamental evolution driven by the demands of modern manufacturing. This

2025/12/10 14:34

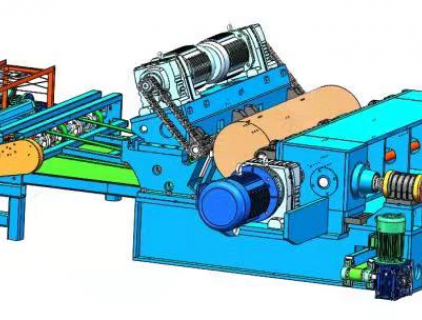

In the world of wood-based panel production, from plywood to LVL, the veneer peeling lathe stands as a cornerstone of the manufacturing process. The quality, efficiency, and economics of the entire operation hinge on this critical machine. For manufacturers, the choice between the two primary types

2025/12/04 15:36

In the high-stakes world of fine woodworking and luxury interior design, the value of a finished product is profoundly influenced by the quality of its surface. Precious veneers, such as those sliced from Walnut and White Oak with a delicate thickness of 0.5mm or less, represent the pinnacle of

2025/11/25 10:27

Veneer Grading: How Shine ’s Intelligent System Unlocks Hidden ValueIn the highly competitive world of wood processing, the margin between profitability and loss often hinges on the ability to maximize the value of every single raw material. For veneer-based products, this critical function is

2025/11/20 10:22

Why More Plywood Manufacturers Are Adopting Advanced Roller Veneer Dryer for Veneer?The plywood manufacturing industry is undergoing a significant technological transformation, marked by a decisive shift away from traditional drying methods towards advanced roller dryer systems. This trend is not

2025/11/13 15:04

What Is Veneer Core Plywood?If you’ve ever touched a smooth piece of furniture or admired fine cabinetry, chances are you’ve met veneer core plywood. So, what is veneer core plywood exactly? In simple terms, it’s a type of hardwood plywood that consists of multiple veneer layers, each glued

2025/11/06 09:55

Comparing Plywood, Eco-Board, OSB, and MDF for Your Project Plywood: The All-Rounder for StabilityPlywood, constructed from multiple thin wood veneers (typically 3-13 layers) glued together with their grains perpendicularly aligned, is a versatile and stable option. Common base woods include poplar

2025/10/31 10:18

After undergoing the intense heat of the drying process, wood veneers are not immediately ready for use. A critical, yet often overlooked, step is the resting or conditioning period. This phase allows the veneers to adapt to the ambient environment, balance internal moisture, and release built-up

2025/10/22 16:59

In recent years, the international wood veneer industry has shown multidimensional structural changes, facing both reduced demand and supply chain challenges, as well as new opportunities arising from technological innovation, green transformation, and regional cooperation. 1、 Differentiation of

2025/07/17 16:49

Submitted successfully

We will contact you as soon as possible

Close