Best Veneer Dryer for Wood Processing

The Shine Veneer Dryer is a state-of-the-art drying solution designed for the wood processing industry. With advanced temperature control and energy-efficient technology, it ensures uniform drying of wood veneers, preventing cracks and deformations. Ideal for furniture manufacturing, plywood production, and more, this industrial veneer dryer offers reliable performance at an affordable price. Choose Shine for high-quality veneer drying equipment that meets your production needs.

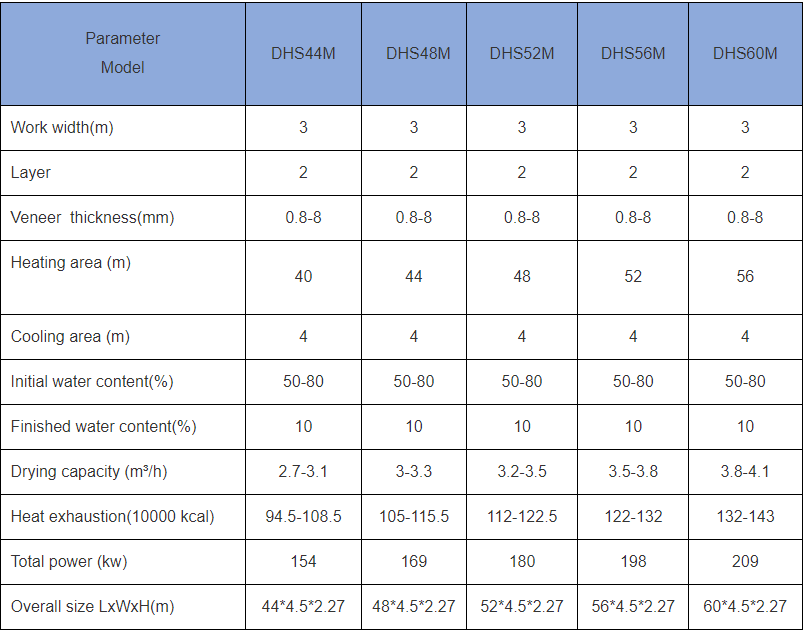

Product Details

Best Veneer Dryer for Wood Processing

Using an environmentally to fire crushed wood chips, waste wood, and other materials, materials in the biomass burner into hot air, to provide heat energy for the veneer dryer. This heat source method is both environmentally friendly and cost-saving which greatly reduces the wood drying cost. The hot air absorbs the wind from the heat exchanger through the fan and is blown to the wood veneer inside the dryer. The hot air is in full contact with the eucalyptus wood veneer to complete the drying process. The upper and lower rollers rotate relative to each other, the upper roller rotates by its weight and the lower roller is kept immobile by the bearing. The eucalyptus wood veneer enters from the feed opening of the dryer and runs forward through the relative rotation of the rollers. The veneer dryer is equipped with a temperature controller and frequency converter of traction motor, which can automatically adjust the speed according to the thickness of the veneer and the customized moisture content, to realize precise drying of the veneer in the process of traveling to achieve the best drying effect.

Features of Best Veneer Dryer for Wood Processing

High-efficiency drying with uniform moisture distribution

Energy-saving design reduces operating costs

Durable construction for long-term use

Easy to operate and maintain

Applications

Furniture Manufacturing: Ensure your furniture components are dried to the highest standards.

Flooring Production: Achieve consistent moisture levels for superior flooring products.

Cabinetry: Perfect for drying cabinet components with precision and efficiency.

Construction Materials: Ideal for drying wood used in construction applications.

Benefits

Improved Product Quality: Achieve superior drying results, enhancing the overall quality of your wood products.

Cost Savings: Reduce energy consumption and minimize waste, leading to significant cost savings.

Increased Productivity: Faster drying times and efficient operation help boost your production output.

Reliable Performance: Trust in the durability and reliability of Shine's advanced drying technology.

Packaging & Shipping

Company Strength

In the pursuit of high-efficiency environmental protection, and quality in the wood processing industry, as a veneer dryer manufacturer, the Shine has become a bright star in the industry with its excellent performance, advanced technology, and intelligent design. We know that drying is not only the key step to ensure the stability of the veneer in every process of veneer but also the foundation to improve the quality of the product and prolong its service life. Therefore, Shine has created a series of high-efficiency veneer dryers aiming to bring an unprecedented drying experience to global wood processing enterprises.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close